- Scarborough, ON M1P 3E6

- 1,280

Description

Item number: 056396

-

Product Overview

This compact hexagonal high-temperature ceramic kiln features a space-saving design, high-temperature performance, uniform heating, user-friendly operation, safety, and energy efficiency. It is primarily used for firing small ceramic products, sintering glazes, teaching demonstrations, and creative projects, making it widely applicable in homes, classrooms, art studios, and scientific research laboratories.

Product Parameters

Voltage: AC220V

Phase Number: 1

Power: 2.5kW

Current: 11.5A

Interior Diameter: 10.8"(27.5cm)

Interior Depth: 9.0"(23cm)

Cubic Feet: 0.6ft3

Circuit Breaker: ≧2P20A

Cable Specifications: ≥ 2.5m2

Boron Plate Diameter: 7.9"(20cm)

Capacity Reference: Fits 15 dolls (H75xW60mm) or 10 cups (H95xW70mm)

Maximum firing temperature: 1280℃

Conventional firing temperature: 1220℃

Package size: 28.7"*26.8"*39.0" (73cm*68cm*99cm)

Net weight/Gross weight: 181.9lbs(82.5kg)/253.5lbs(115kg)

Product Features & Advantages

exagonal Structure

The hexagonal structure efficiently utilizes the furnace space and ensures even heat distribution, guaranteeing uniform heating of ceramic products during the firing process and reducing the risk of deformation or cracking. The use of high-temperature molybdenum disilicide (MoSi2) heating elements significantly increases the maximum firing temperature and extends the service life of the kiln.

Thickened Insulation Layer

Using high-temperature polycrystalline wool provides excellent thermal insulation and high-temperature resistance, effectively reducing heat loss and improving the uniformity and stability of the temperature inside the furnace.

Safety Lock

It adopts a 180° up-and-down latch with an ergonomic design, making it easy to control and operate. The reinforced design ensures the latch is more stable, preventing accidental opening and protecting the operator's safety.

Heat Dissipation

At temperatures below 300 degrees, the lid should be removed to facilitate rapid moisture dissipation. When the temperature exceeds 300 degrees, the lid should be closed to maintain heat. During cooling, once the temperature drops below 300 degrees, the lid can be removed to accelerate cooling.

Handle

The handle on top of the machine allows the furnace lid to be opened quickly, making it convenient for operators to inspect or load/unload ceramic products, thereby improving work efficiency.

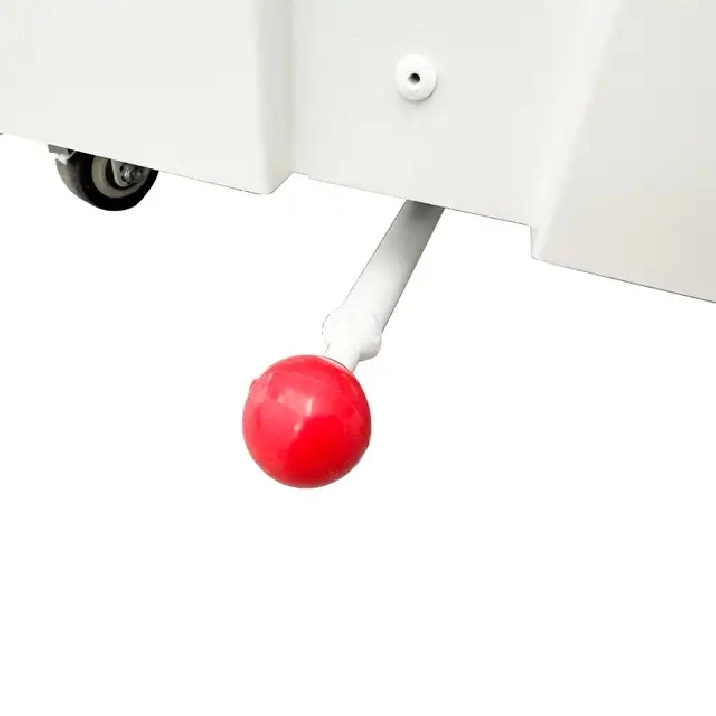

Rapid Cooling

To achieve rapid cooling, simply pull the lever outward, which will swiftly lower the furnace temperature, reduce cooling time, and enhance production efficiency.

Hydraulic Rod

The hydraulic system, designed with high load-bearing capacity, enables automatic lifting of the lid when opening, making it easier to open the kiln cover and ensuring convenient operation.

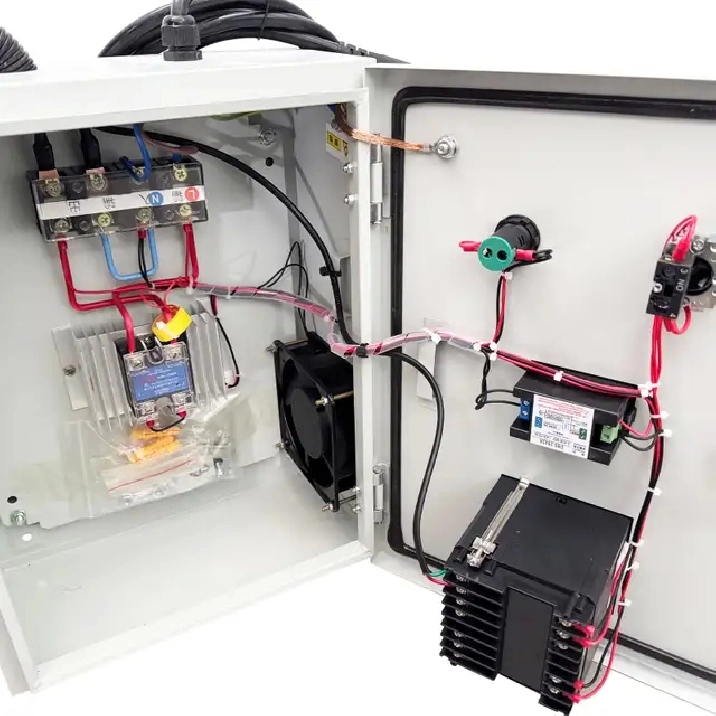

Split-type Control Box

The split-type control box is separated from the main unit and can be flexibly installed in different locations according to actual needs. Its button-operated design ensures ease of use.

Caster

The casters allow the equipment to be easily moved, enabling flexible positioning between different work areas. Two of the casters are equipped with braking functions, which can secure the machine and prevent it from moving.

Item Included: 056396

Electric Kiln High Temperature Heating Machine *1 Support Column *5

Boron Plate *2 Alumina Disc *2

Kiln Lid *1

Heat-resistant Glove *2

Notice

1.Limited stock, please purchase ASAP if you want it.

2.Before pickup, please call us to make sure.

3.The price will be adjusted when there's large fluctuations in exchange rates and raw material costs.

4.Advertising price does not include the tax.

Warehouse Address:

2220 Midland Ave., Unit 60AP (Administration Park)

Scarborough, ON M1P3E6

Business Hours:

Monday - Friday 9:00am - 4:30pm

Saturday & Sunday Closed

* For PICK UP, appointment by phone needed.

Tel: 647-350-2889 416-727-3877

https://asc365.com/newproductdetail.asp?productid=056396&typeid=2167

Details

- Cashless payment:

- For Sale By: Business

- Curbside pick up:

- Shipping:

- Fulfillment: Shipping,Curbside pick up

- Drop off / Delivery:

- Cash accepted:

- Condition: New

- Payment: Cashless payment,Cash accepted